In the HVAC (Heating, Ventilation, and Air Conditioning) industry, the assembly of sheet metal components is a critical process that ensures the efficiency, reliability, and durability of the systems. Among the various methods of joining metal sheets, clinching has emerged as a preferred solution due to its strength, cost-efficiency, and environmental benefits. Clinching is a cold-forming technique that provides a strong mechanical connection without the need for welding, adhesives, or fasteners, making it ideal for the assembly of ductwork, air conditioners, and ventilation systems.

In this blog, we will explore what clinching is, how it works, and the benefits it offers specifically for sheet metal assembly in the HVAC industry.

What is Clinching?

Clinching is a mechanical joining process used to connect two or more sheets of metal by creating a localized deformation. This process involves compressing the sheets between a punch and a die, which forces the materials to interlock and form a secure joint. Unlike traditional methods like welding or using fasteners, clinching does not require heat or additional materials such as rivets or screws.

This method is particularly useful for lightweight and thin sheet metals, which are commonly used in HVAC systems. Clinching is not only efficient but also ensures an airtight and vibration-resistant joint, which is essential for the proper functioning of HVAC systems.

How Does Clinching Work?

The clinching process involves the following steps:

- Material Placement: The sheets of metal to be joined are placed between a punch and a die.

- Punching: The punch moves downward, pressing the sheets into the die cavity. This action causes the material to flow and form an interlock between the sheets.

- Forming the Joint: As the punch applies pressure, the material flows into the die, creating a button-like interlock that holds the sheets together securely.

- Completed Joint: Once the punch retracts, a strong, permanent joint is formed without the need for additional fasteners or adhesives.

Clinching can join multiple layers of metal and can be used on coated materials like galvanized steel or aluminum, making it highly versatile for HVAC applications.

Benefits of Clinching in HVAC Sheet Metal Assembly

Clinching offers several advantages over traditional joining methods, especially in the context of HVAC sheet metal assembly:

- Airtight and Leak-Proof Joints

HVAC systems rely on airtight ductwork to ensure proper airflow and energy efficiency. Clinching creates a leak-proof joint by deforming the metal to form a tight interlock. This helps HVAC manufacturers create systems that minimize energy loss and ensure consistent airflow, which is critical for maintaining system efficiency.

- Vibration-Resistant Connections

In HVAC systems, vibrations caused by moving air, fans, and compressors can loosen mechanical joints over time. Clinching forms a robust, vibration-resistant connection that remains secure even under dynamic loads, ensuring long-term reliability of the system.

- No Need for Fasteners or Heat

One of the biggest advantages of clinching is that it eliminates the need for fasteners such as screws, bolts, or rivets. This not only reduces material costs but also speeds up the assembly process. Additionally, since clinching is a cold-forming process, there is no need for heat, which can distort or weaken the metal—making clinching especially ideal for thin-gauge sheet metals commonly used in HVAC systems.

- Environmentally Friendly

Clinching does not require any consumables like welding rods or adhesives. By eliminating the need for additional materials, clinching is a more sustainable and environmentally friendly option for manufacturers. It also minimizes the use of energy compared to welding, making it a greener choice for HVAC production.

- Suitable for Coated and Painted Metals

HVAC systems often use galvanized or painted sheet metals to prevent corrosion. Welding or other heat-based joining methods can damage these coatings, reducing the longevity of the materials. Clinching, on the other hand, preserves the protective coatings, ensuring that the assembled components maintain their resistance to rust and wear over time.

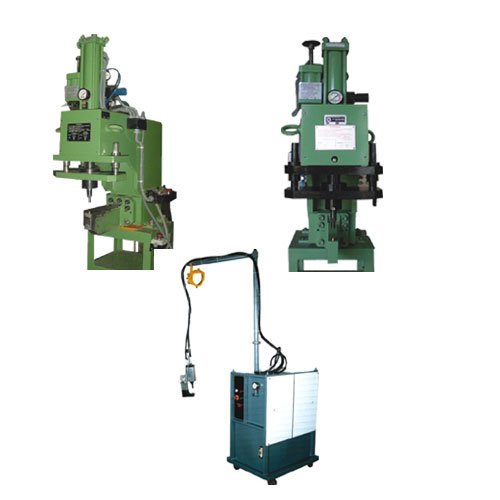

- High-Speed, Automated Process

For high-volume production in the HVAC industry, clinching is a perfect solution. Clinching machines can be easily integrated into automated production lines, allowing manufacturers to increase production rates while maintaining consistent quality. This is crucial for large-scale projects like commercial HVAC systems or residential ducting networks.

Applications of Clinching in HVAC Manufacturing

Clinching has become the preferred method for joining sheet metal components in HVAC systems due to its speed, strength, and cost-efficiency. Some common applications of clinching in HVAC manufacturing include:

- Ductwork Assembly: Clinching is ideal for creating airtight connections between sheets of metal used in air ducts. This ensures that air flows efficiently through the system without leakage.

- Air Conditioner Casings: The lightweight yet strong connections formed by clinching make it perfect for assembling air conditioner housings and casings.

- Ventilation Systems: Clinching can be used to assemble parts of ventilation units, ensuring they are resistant to vibrations and capable of maintaining structural integrity over time.

- HVAC Mounting Frames: For HVAC units that require mounting frames, clinching provides a strong and vibration-resistant solution for securing sheet metal frames to other components.

Clinching vs. Traditional Joining Methods in HVAC

While welding and screwing are still widely used in HVAC manufacturing, clinching offers several key advantages over these traditional methods. Welding requires significant heat, which can warp thin metal sheets, and screws or rivets can loosen over time, especially in applications subject to vibration. Clinching offers a strong, secure joint without these drawbacks, making it an ideal choice for sheet metal assembly in HVAC systems.

For more information on rivet-free sheet metal assembly solutions, check out our detailed post on orbital riveting for HVAC systems. Additionally, discover how automated screw tightening machines are enhancing precision in HVAC manufacturing on our dedicated product page.

As HVAC systems become more sophisticated, the need for efficient and reliable assembly techniques continues to grow. Clinching has emerged as a highly effective method for joining sheet metal components, offering airtight, vibration-resistant joints that improve the overall performance of HVAC systems. Its ability to create strong connections without fasteners, heat, or additional materials makes it an ideal solution for modern HVAC manufacturing.

If you’re looking to enhance your HVAC production line with clinching machines, contact Orbital System (Bombay) Pvt. Ltd. for tailored assembly solutions designed to meet your specific needs.