Orbital System (Bombay) Pvt. Ltd.: Manufacturer, Supplier, and Exporter of Auto Screw Feeding & Tightening Machines

At Orbital System (Bombay) Pvt. Ltd., we provide advanced Auto Screw Feeding & Tightening Machines designed for precision, speed, and efficiency in automated screw tightening processes. These machines streamline production by feeding and driving screws automatically, reducing manual labor, and increasing productivity. Our systems are suitable for various industries including electronics, automotive, home appliances, and general manufacturing, where precision and reliability are essential for screw fastening tasks.

With options ranging from handheld to robotic screw tightening machines, we ensure that every model meets the highest standards of performance, helping industries to achieve faster production times, lower error rates, and consistent results. Our Auto Screw Feeding & Tightening Machines are adaptable to various screw types, shapes, and sizes, and are compatible with different screwdrivers, making them versatile tools for diverse manufacturing needs.

+91 98210 94824

paramjit.seehra@gmail.com

An Auto Screw Feeding & Tightening Machine is an automated system that feeds screws and drives them into components with precision and speed. The machine automatically aligns, positions, and screws parts together, eliminating the need for manual screw handling. This technology ensures consistent torque application, reducing the chances of over-tightening or loose screws. It is ideal for high-speed production environments that demand precision and efficiency.

These machines are available in different formats, such as handheld, stand-alone, and robotic systems, allowing for a wide range of applications depending on production requirements.

The Handheld Auto Screw Tightening Machine is a portable, easy-to-use solution designed for operators who need flexibility and speed in screw fastening. It allows minimal push-down force, reducing operator fatigue, and can be equipped with a torque arm or toggle arm for added support.

The Stand-Alone Auto Screw Tightening Machine offers a high-speed, fully automatic solution for assembly lines requiring consistent and reliable screw fastening. This machine can handle various components and screw types, making it a universal tool for diverse manufacturing processes.

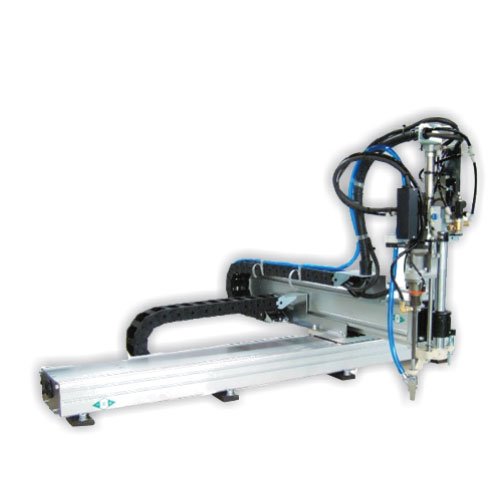

The Robotic Auto Screw Tightening Machine offers the highest level of automation and precision. Equipped with options for desktop, cartesian, and SCARA robots, this machine is perfect for high-volume production environments where accuracy and speed are critical.

The Screw Array Machine is engineered to handle multiple screws simultaneously, driving them into position in a specified array with high accuracy. This technology eliminates manual screw placement, reducing production times and operator fatigue while improving overall product quality.

In addition to our standard models, we offer non-standard machines customized to meet specific production needs. These machines can be designed to accommodate unique component shapes, sizes, and screwing requirements, offering a tailored solution for your specific application.

Electrical Industry

Use: In the electrical industry, precise and efficient screw tightening is essential for assembling components such as neutral links, terminals, meter boxes, MCBs, electric switches, and PCB cards. The Auto Screw Feeding & Tightening Machines provide high-speed and consistent screw fastening, ensuring reliability and safety in electrical assemblies.

Components: Neutral links, meter boxes, PCB cards, electric switches, MCBs.

Products: Handheld, stand-alone, and robotic machines for high-speed, precision screw tightening.

Automotive Industry

Use: The automotive industry requires precise and reliable fastening solutions for critical components like speedometers, engine covers, wiper motor bodies, and carburetors. Our Auto Screw Feeding & Tightening Machines ensure consistent torque and fast assembly, improving production efficiency and product quality.

Components: Speedometers, engine covers, wiper motors, window regulators, fuel tank covers, carburetors.

Products: Handheld, stand-alone, and robotic machines for high-speed automotive assembly.

Consumer Goods and Electronics Industry

Use: In the consumer goods and electronics industry, automated screw tightening is essential for assembling small, delicate components in products like mobile phones, televisions, and home appliances. Our machines ensure that each screw is fastened with precision, reducing assembly time and improving product reliability.

Components: Mobile phones, televisions, CPUs, water purifiers, ceiling fans, set-top boxes.

Products: Handheld and robotic machines for high-volume electronics and consumer goods production.

Home Appliance Industry

Use: The home appliance industry demands high-speed and reliable screw fastening for products such as washing machines, refrigerators, water purifiers, and kitchen appliances. Our Auto Screw Feeding & Tightening Machines offer fast, precise assembly, reducing cycle times and improving overall production efficiency.

Components: Washing machines, refrigerators, water purifiers, kitchen appliances.

Products: Stand-alone and robotic machines for high-speed home appliance assembly.

General Industry and Manufacturing

Use: Auto Screw Feeding & Tightening Machines are versatile tools used across various general industries for assembling products like door locks, furniture, toys, gas regulators, and measuring instruments. These machines provide efficient and precise screw fastening, improving production speed and reducing errors.

Components: Door locks, furniture, toys, staplers, gas regulators, measuring instruments.

Products: Handheld and non-standard machines for general manufacturing and assembly.

+91 98210 94824

paramjit.seehra@gmail.com

For more information on how our Auto Screw Feeding & Tightening Machine can enhance your manufacturing process, get in touch with Orbital System (Bombay) Pvt. Ltd. today.

© 2024 Orbital Systems (Bombay) Private Limited. All rights reserved.

Designed by Vebiotic Web Solutions Marketing by Adinads